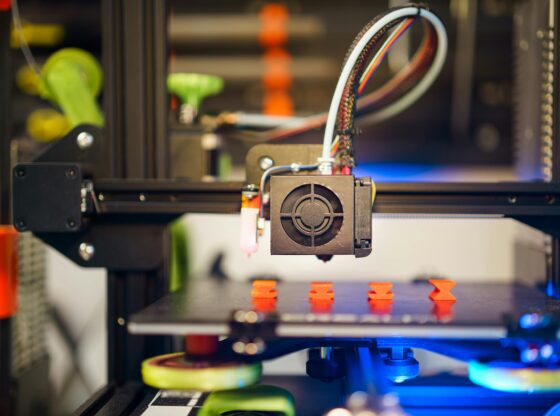

Not very far in the past, creating another item implied extended periods of difficult work, with talented specialists working endlessly on models. This is not true anymore. The ascent of 3D printing has reformed planning and assembling, turning the customary interaction on its head.

Envision — where it once required a long time to make a solitary model, originators can now see their manifestations emerge for the time being.

Organizations, of all shapes and sizes, are getting on to this pattern, utilizing 3D printing to smooth out their prototyping cycle, consequently speeding up the excursion from thought to customer-facing facade.

For extra data on 3D printing gum, which is in many cases utilized in this cycle, devotees and experts can dig further into the subject. Gone are the times of mystery and squandered materials; in comes another period where each model is exact, practical, and quick.

Redone Spare Parts On-Request

The auto business is infamous for the difficulties related to spare parts on the board. 3D printing upsets this perspective by offering makers the capacity to deliver spare parts on request and to correct determinations. This on-the-fly creation of extra parts kills the requirement for huge inventories of pre-produced parts and decreases the expenses related to capacity and coordinated operations.

With 3D printing, makers can answer quickly to explicit fix or substitution needs, improving generally speaking productivity in support and fix activities. This recovery time also adds to the cost of investment funds and is a more feasible way to deal with stock administration.

Lightweight, Solid, and Solid Car Parts

Added substance assembling of composite materials is reshaping the scene of car parts. The utilization of 3D printing considers the making of parts that are lightweight as well as show upgraded sturdiness and strength. This has critical ramifications for the plan and execution of current vehicles. Lightweight auto parts add to eco-friendliness, making vehicles all the more harmless to the ecosystem and savvy. The strength and sturdiness of 3D-printed parts additionally lead to more secure and stronger vehicles. Therefore, car makers can deliver vehicles that are more proficient as well as gloat further developed execution and security highlights.

The mix of 3D printing in the car business addresses a change in perspective in assembling processes. From quick prototyping to on-request creation of extra parts and the making of lightweight, solid parts, 3D printing is upgrading productivity and pushing the limits of what is conceivable in car plans. As this innovation keeps on propelling, we can hope to observe considerably more noteworthy development, at last forming a future where car production is more dexterous, maintainable, and receptive to the advancing necessities of the market.

Developments IN MATERIAL Choice

The scope of materials accessible for 3D printing keeps on extending, opening up additional opportunities for planning and assembling. At first restricted to plastics, 3D printing currently integrates metals, pottery, composites, and, surprisingly, biocompatible materials. This assorted material determination considers the development of utilitarian models, end-use parts, and, surprisingly, complex designs. The capacity to join numerous materials inside a solitary print further improves the flexibility of 3D printing, empowering the production of half-breed objects with exceptional properties.

Molding THE Eventual Fate of Plan AND Assembling

3D printing is ready to alter the eventual fate of plan and assembling. It offers creators the exceptional opportunity to make perplexing, altered plans that were previously unattainable. The innovation enables independent companies and new businesses to rejuvenate their thoughts without critical monetary obstructions. As 3D printing proceeds to develop and turn out to be more open, we can hope to see further headways, for example, multi-material printing, sped up, and improved goals. The democratization of assembling through 3D printing holds the possibility to reshape businesses and enable people to become makers and trend-setters.

Eager Item Advancement 3D PRINTING

3D printing has introduced another time of plan and assembling, opening boundless conceivable outcomes and changing enterprises. Its capacity to make complex plans, tweak items, and lessen squandering makes it an integral asset for development. As 3D printing innovation keeps on propelling, we can expect striking forward leaps and applications that will reshape how we configure, produce, and cooperate with objects. What’s in store holds an existence where innovativeness exceeds all rational limitations, and 3D printing fills in as the scaffold for creative minds and unmistakable reality.

Difficulties and contemplations

While 3D printing offers many benefits, it likewise accompanies specialized difficulties, for example, material impediments and post-handling necessities. These difficulties can influence the quality and cost-adequacy of the eventual outcome — something producers should cautiously consider while embracing 3D printing.

3D printing raises moral and ecological worries, especially regarding material waste and energy utilization. While innovation can decrease squandering in certain viewpoints, taking into account its general ecological impact is fundamental. Capable use and material reusing are essential.

The underlying interest in 3D printing innovation can be high, particularly for modern-grade machines. In any case, the drawn-out benefits frequently offset the expenses, the reserve funds from decreased squandering and expanded productivity. Money-saving advantage examination is fundamental for organizations considering taking on this innovation.

Future possibilities

The fate of 3D printing looks encouraging, with progressing innovative work pointing toward defeating current restrictions. New materials and more proficient printing techniques are ceaselessly being created, and these advancements could additionally adjust 3D printing to incline to produce standards.

Advancements in speed, material utilization, and customization abilities will additionally lessen waste and increment proficiency. These advancements will make 3D printing a much more alluring choice for lean assembling.

3D printing can upset assembling by adjusting intimately with lean standards. It offers an interesting mix of customization, effectiveness, and waste decrease that customary assembling strategies battle to accomplish. This groundbreaking innovation is setting new guidelines in assembling, making it a vital apparatus for any organization embracing lean assembling standards successfully.

Ben Herzberg is an accomplished tech pioneer and book writer with a foundation in endpoint security, examination, application, and information security. Ben filled jobs like the CTO of Cynet and Overseer of Danger Exploration at Imperva. Ben is the Central Researcher for Satori, the DataSecOps stage.